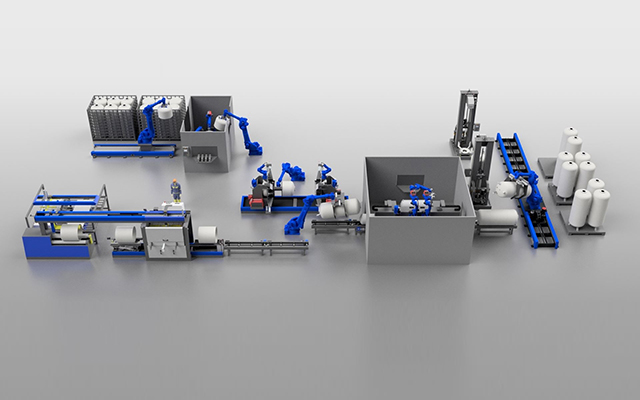

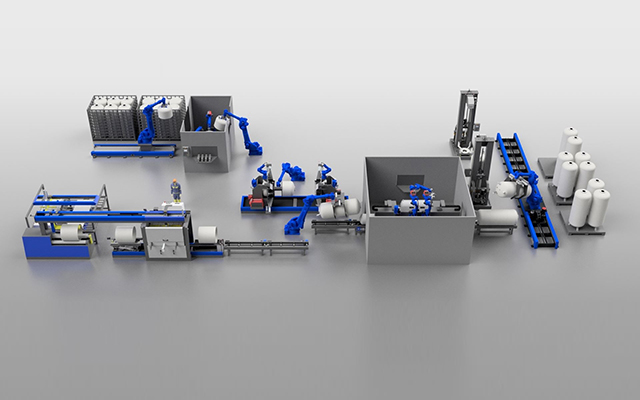

A Gas tank robot production line is a highly specialized automated manufacturing system designed to produce a wide range of pressure vessels, including LPG cylinders, propane tanks, natural gas containers, industrial storage tanks, and household gas cylinders. These tanks are widely used in residential cooking, heating, industrial fuel supply, chemical processing, and energy storage.

Traditional methods of gas tank production relied heavily on manual welding, cutting, and inspection, which were prone to inconsistencies, human error, and safety risks. With the rising global demand for reliable and safe gas storage, manufacturers have increasingly turned to automation. By integrating robotics, CNC cutting, intelligent welding, automatic assembly, and non-destructive testing (NDT), a robotic gas tank production line ensures high productivity, superior welding quality, and compliance with international safety standards.

Such production lines not only enhance efficiency but also improve workplace safety by reducing direct human exposure to hazardous welding and cutting processes. They are adaptable for different tank sizes, wall thicknesses, and materials, providing flexibility for manufacturers serving both domestic and industrial sectors.

Key Parameters and Technical Specifications

The performance and effectiveness of a gas tank robot production line are determined by several critical parameters:

Tank Size Range

Material Compatibility

Carbon steel, stainless steel, alloy steel.

Optional support for composite materials.

Production Capacity

200,000–1,000,000 tanks annually depending on line configuration.

Cycle time per tank: 2–6 minutes.

Robotic Welding System

Multi-axis robotic arms for seam, circumferential, and longitudinal welding.

Welding processes: GMAW, TIG, or SAW, depending on thickness.

Real-time seam tracking and adaptive control.

Cutting and Forming Accuracy

CNC plasma, laser, or stamping technology.

Tolerance: ±0.5 mm for cutting, ±1° for bending or stamping.

Automation Modules

Shell forming and trimming.

Bottom/top head assembly.

Robotic welding stations.

Surface treatment (blasting, painting, coating).

Leak testing and hydrostatic testing.

Inspection Systems

NDT: ultrasonic testing, X-ray inspection, or magnetic particle inspection.

Automated leak detection using air pressure or water immersion.

Control System

PLC + HMI control panels.

IoT-enabled data collection and remote monitoring.

MES/ERP integration for production management.

Energy Efficiency

Safety Standards

Compliance with ISO 4706, EN 1442, DOT, ASME, and CE certifications.

Fire safety systems and emergency stop functions included.

Application Scenarios

Residential Gas Supply

Industrial Gas Storage

Propane and butane tanks for manufacturing, metal processing, and construction sites.

Tanks for powering industrial furnaces and generators.

Automotive and Transportation

Energy and Power Sector

Chemical and Petrochemical Plants

Storage of industrial gases, including ammonia, propane, and specialty chemicals.

Tanks designed to withstand corrosive and high-pressure environments.

Export and International Trade

Operation and Usage Instructions

1. Pre-Operation Preparation

Inspect raw materials: steel plates, heads, valves, and fittings.

Calibrate robotic welding arms and CNC cutting machines.

Configure PLC control system with tank design parameters.

2. Shell Forming

Steel plates are cut to required dimensions by CNC plasma or laser machines.

Plates are bent or rolled into cylindrical shapes.

Robotic systems align and tack weld the shell.

3. Head Fabrication and Assembly

Top and bottom heads are pressed or stamped.

Automated trimming ensures uniform edges.

Heads are positioned and joined to the cylinder body by robotic arms.

4. Robotic Welding

Circumferential and longitudinal welds are executed by robotic welding stations.

Laser-guided seam tracking ensures precision.

Welding parameters adjust automatically based on real-time sensor feedback.

5. Heat Treatment and Stress Relief

6. Testing and Inspection

NDT methods check weld quality.

Hydrostatic and pneumatic testing verify leak-proof performance.

Defective units are flagged for rework.

7. Surface Treatment and Coating

Sandblasting removes impurities and welding scale.

Robotic painting systems apply corrosion-resistant coatings.

Optional powder coating or galvanization for extended lifespan.

8. Assembly and Finishing

Valves, safety caps, and accessories are installed.

Final marking, labeling, and QR code tagging for traceability.

9. Packaging and Logistics

Maintenance Guidelines

Daily: Check robot calibration, welding torch cleanliness, and conveyor lubrication.

Weekly: Inspect cutting nozzles, welding consumables, and sensors.

Monthly: Test safety systems, update PLC software, and perform NDT sample checks.

Yearly: Overhaul robotic arms, replace wear parts, and recalibrate inspection equipment.

Frequently Asked Questions (FAQs)

Q1: What sizes of tanks can the robot production line manufacture?

A: The system can produce small household cylinders (5–50L), medium tanks (100–250L), and industrial tanks up to 500L. Customization is possible for larger capacities.

Q2: What welding processes are supported?

A: GMAW (MIG/MAG), TIG, and submerged arc welding. The system selects the process based on tank thickness and material.

Q3: How many operators are needed?

A: A fully automated line requires 3–6 supervisors. Semi-automated configurations may require 10–15 operators.

Q4: What certifications can be achieved with these tanks?

A: The system complies with ISO, EN, DOT, and ASME standards, making the products export-ready.

Q5: How fast is the production cycle?

A: Depending on the tank size, one unit can be completed within 2–6 minutes.

Q6: How is product quality ensured?

A: Integrated NDT, hydrostatic tests, and automated inspection ensure compliance. Real-time monitoring detects deviations instantly.

Q7: Can the system produce different tank models on the same line?

A: Yes. With modular programming and quick-change fixtures, the line can switch between different capacities and designs.

Q8: What is the typical service life of the equipment?

A: With proper maintenance, robotic production lines can operate efficiently for 15–20 years.

Q9: How much floor space is required?

A: A standard line requires 3000–5000 m². Compact versions are available for smaller facilities.

Q10: How is safety managed?

A: Multiple safety systems are included: emergency stop buttons, fire suppression systems, robotic barriers, and real-time monitoring of gas leaks during testing.

Advantages of a Robotic Gas Tank Production Line

High Efficiency – Continuous automated workflow reduces cycle time and increases throughput.

Superior Welding Quality – Robotic welding ensures precision and consistency.

Safety Improvements – Operators are not directly exposed to hazardous welding or pressurized testing environments.

Scalability – Capable of adapting to different tank sizes and designs.

Global Compliance – Meets international safety and manufacturing standards.

Cost Reduction – Minimizes labor costs, reduces material waste, and improves energy efficiency.

Traceability – QR code tracking ensures product traceability from raw material to finished product.

Sustainability – Energy-efficient systems and optimized resource utilization reduce environmental impact.

Conclusion

The Gas Tank Robot Production Line is a future-oriented solution for the pressure vessel manufacturing industry. It combines robotic precision, advanced automation, and rigorous safety standards to deliver tanks that meet both domestic and international requirements. From residential LPG cylinders to industrial gas storage units, this production line is versatile, efficient, and reliable.

In the era of Industry 4.0, integrating robotic production lines allows manufacturers to meet growing demand, reduce production costs, and maintain competitive advantage in a global market. By ensuring safety, consistency, and scalability, gas tank robotic manufacturing systems represent the backbone of modern energy infrastructure.

WhatsApp

WhatsApp Phone

Phone